Cookies help us deliver our services. By using our services, you agree to our use of cookies.

English

Direct Drive Module Series

DD Motor Series

• High dynamic motion::Fast response capability, application in high-throughput applications like high-speed pick-and-place and on-the-flying inspection during motion.

• High Position Accuracy:Direct-drive load minimizes transmission errors, achieving high position accuracy.

• Low Noise and Vibration:No gears, belts, or other transmission mechanisms result in lower noise and vibration during operation.

• Low Motor Maintenance Cost:Fewer components lead to lower maintenance requirements and a longer lifetime.

• Diverse Application Scenarios:Widely used in visual alignment, optical inspection, precision assembly, fiber optic alignment, and other fields.

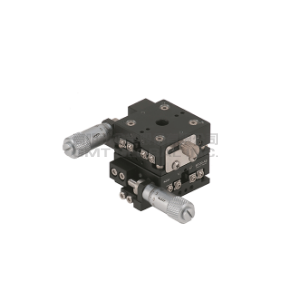

GLM Micro-Alignment Stage

• High response speed:The direct-drive design enables the platform to respond quickly, making it suitable for high-utilization rate requirements such as high-speed pick-and-place and on-the-fly inspection.

• High-precision positioning:The XYT platform is equipped with a high-precision optical ruler, which enables the platform to have high-precision performance.

• Compact Design:The internal structure is compact, with a linear motor and an integrated base design, making it suitable for applications with limited space.

• Flexible:The optical scale has various resolutions and can be customized to meet different process requirements.

• Multiple application scenarios:It is widely used in visual alignment, optical inspection, precision assembly, fiber optic alignment and other fields.

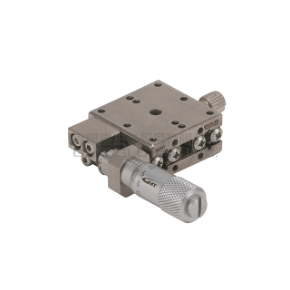

GLM-Z Axis Miniature Stage Series

• Direct-Drive Motion:Powered by a voice coil motor with integrated damping for enhanced stability. No reduction gear device means lower inertia and minimal wear.

• Compact Travel & Load Capacity:The stroke is 8mm. Depending on the model, it supports maximum loads of 1 kg & 1.5 kg.

• Stackable & Lightweight Design:Designed for seamless integration with X/Y axis miniature stages. Its small footprint and lightweight build enable high dynamic response — perfect for short-stroke, high-accuracy motion control.

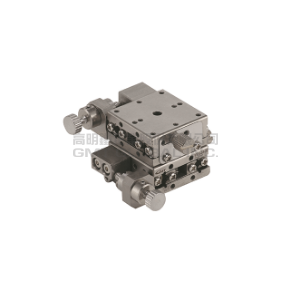

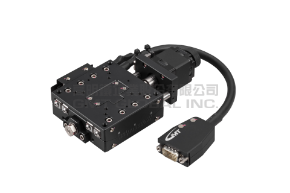

XYZ Three-Axis Motion Module

• Modular Stackable Design:Configurable in multiple layouts to meet diverse customer requirements. Each axis is built as an independent module for flexible integration.

• Direct-Drive Precision:Equipped with high-rigidity linear guides and high-performance drivers. Achieves sub-100-nanometer repeatability and positioning accuracy.

• Broad Application Range:Ideal for fiber coupling, precision inspection, semiconductor testing, IC packaging, object measurement, and micro-engineering tasks.

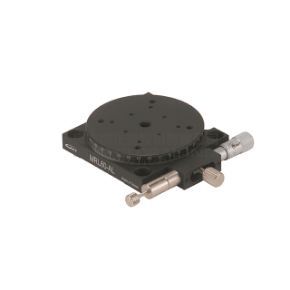

XYZT Four-Axis Module

• An exclusive design solution of semiconductor wafer processing and inspection.

• Utilize a direct-drive motor as the primary power and optimize the stable movement in cross-roller guide with high rigidity.

• Our axis module can achieve the nanometer-level tolerance and ensure the high-speed performance.

• Modular design enables the flexible, adaptable, and various configurations based on customer requirements.

• Our axis module provides high precision motion control solutions which is widely applied in optical communication, semiconductor testing, visual inspection, and micro engineering fields.

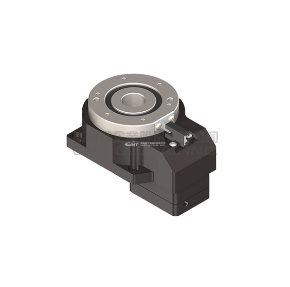

ZR motor series

• Modular Design & Simplified Assembly:The ZR Motor Series boasts a compact design with high integration. Its modular design significantly reduces equipment development and production time.

• High-Precision Positioning & Control:Achieve micrometer-level position control with the ZR Motor Series. It offers a linear repeat positioning accuracy of ±0.5μm and a rotary repeat positioning accuracy of ±0.01∘. Furthermore, programmable control enables equipment to gently touch component surfaces with precise force (<±1g), minimizing damage.

• High Speed & Acceleration:Compared to traditional rotary servo motor and ball screw combinations, ZR-axis linear motors offer a clear advantage in speed, capable of achieving higher speeds and accelerations.

• Low Electrical Interference & High Stability:There's no need for complicated wiring between the ZR motor, driver, and the controller. This design minimizes electrical wiring and interference factors.

-01_3.jpeg)