Cookies幫助我們提供我們的服務。如果要使用我們的服務,您需同意我們使用cookie。

繁體中文

馬達/驅動器

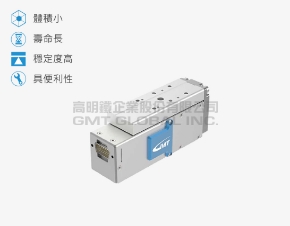

GDL22G-D

★ 二相雙極性微步進驅動器。

★ 體積小,操作方便。

★ 定電流控制。

★ 電源逆接保護。

★ 驅動電流0.2A~2A。

★ 自動電流下降可選擇。

★ 極低的電源損耗,極高的開關效率 。

★ 大範圍信號入力,不需限流電阻及不需切換開關。

★ 8種微分割數可選擇。

GTR24M3

★ 二相單極性微步進驅動器。

★ 小型,價格低。

★ 12段微步進角設定。

★ 輸入電壓DC12V~40A。

★ 高性能、高扭力輸出。

★ 採用先進角度平衡原理微分。

★ 驅動電流0.5A~4A。

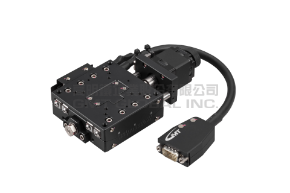

GTR514H-D

★ 五相微歩進驅動器。

★ 1~250多種微分割數可供選擇。

★ 可外部切換二種不同微分割數。

★ 體積小、操作簡單。

★ 電源逆接保護功能。

★ DC5V~24V信號輸入範圍,不需外加限流電阻。

-01_4.jpeg)