♦ Slide Rail Set Composed of two pieces of stainless steel rails with V-grooves, been hardened and ground forming precisely, and rolling elements. Roller type moves in connective 90 degrees alternately to meet requirement of high parallelism and high flatness. In construction, rolling elements are transmitted in cross-contact by precise roller and V-grooves in rails, and in non-circulation. Variation caused by friction resistance is little as well, even almost no difference between starting friction resistance and dynamic friction resistance in light duty. High accuracy moving and loading capacity could be performed. ♦ Slide Rail Set Selection Procedure - Selecting transmission type based on load request

Heavy duty → Roller Light duty → Ball bearing - Deciding roller diameter

- Selecting model type based on installation way

- Confirming specification

- Selecting material based on environment:SUJ2 and SUS440C

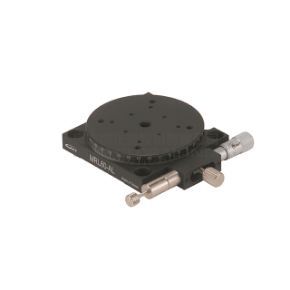

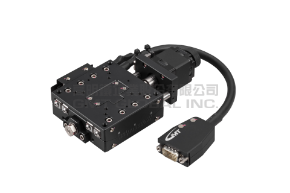

♦ Slide Rail Set Application Wildly applied to accuracy moving device in heavy duty or light duty、in variety of measuring instrument、Printed Circuit Board drilling machine…etc., or slide table used in Optical Measuring Instrument、Precise Gauge in Optical Experiment、precision fine tuning Optical Stage、Operation Mechanism、Survey Device, precise positioning, quantitative movement、X-ray Device & Micro-hole EDM. ♦ Lubrication Function Linear motion needs effective lubrication. Abrasion increase of rolling elements and life decrease would be caused in running without lubrication. - Reduce friction between running parts greatly, so that it could prevent lock and decrease abrasion.

- Forming oil film on rolling surface to reduce abrasion of metal medium to extend life of rolling elements.

- Covering on metal surface to prevent rust.

♦ Slide Rail Set Property - Suited to micro-movement:

Due to tiny friction resistance and almost no difference between starting friction resistance and dynamic friction resistance. In case of tiny movement could also maintain correct trace perform high precision on the linear motion mechanism. - Stability in low speed:

Even in case of light loading, its variation of friction resistance is also tiny, so stability from low to high speed could be kept. - High rigidity、high loading capacity:

Comparison of roller and ball bearing, larger contact area、less elasticity deformation, and non-circulation, great number of units rotating effectively, so high rigidity and large load capacity. - Low noise:

GMT Crossed Roller Slide Rail Set has no circulated rotating, no noise occurred. Using roller slide way with roller retainer makes no noise caused by contact friction in between each rolling unit moves alternately, to ensure a quiet movement motion.

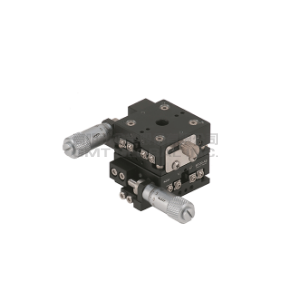

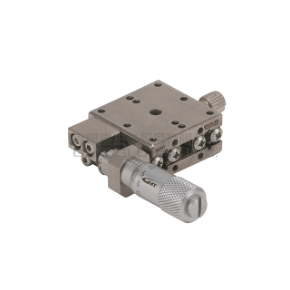

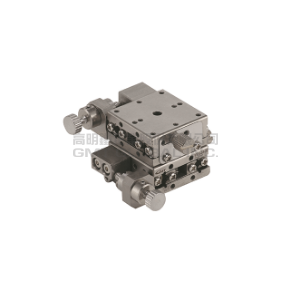

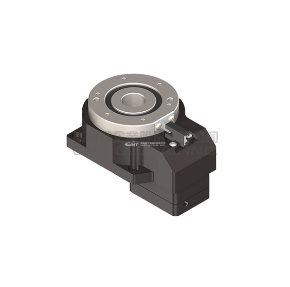

♦ Slide rail set - Roller type:GRV / GRD / GRVP / GRVG / GRDP Composed of precise crossed rollers with hardened steel formed precisely to be V-grooves rail guides to create linear motion element in high accuracy. Limited stroke linear motion system with high rigidity, mid-hard load and spry moment. ♦ Slide rail set - Ball Bearing type:GBV / GBD Composed of ball retainer combined with precise balls bearing arranged in smaller clearance, with the exclusive rails been heat treatment and cryogenic finish, then, forming precisely grinding V-shaped grooves. Limited stroke linear motion system with low friction, light load and high accuracy. | -01_4.jpeg)