Cookies help us deliver our services. By using our services, you agree to our use of cookies.

English

All Categories

Menu Close

- CAD Model Selection

- Support

- Events

- About GMT

- semiconductor and optical communications industries solutions

- Linear Motion Components

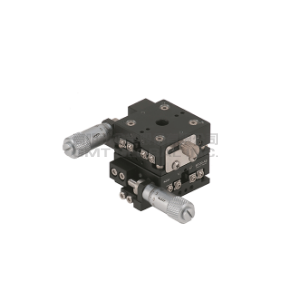

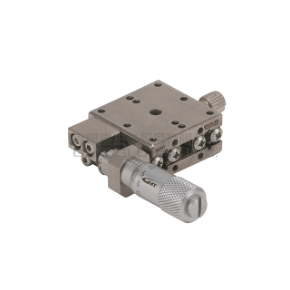

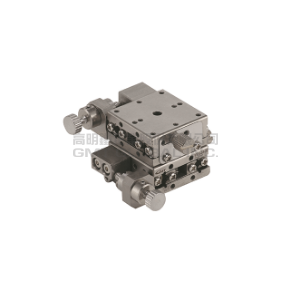

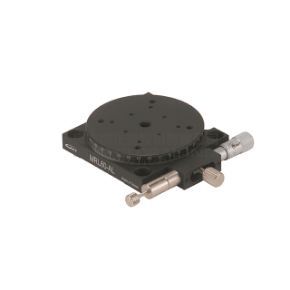

- Manual Stages

- Motorized Stages

- Alignment Stages

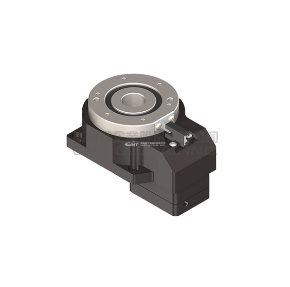

- Direct Drive Module Series

- Automation Module Series

- Optical Components

- Motor/Drive

- Shrink Fit Machine

- Stamping & Mould Components

- INVESTOR AREA

- Contact Us

- NEWS

- All Categories

- CAD Model Selection

- Support

- Events

- About GMT

- INVESTOR AREA

- Contact Us

- NEWS

Stay up to date

Wait...

Customer service

Copyright © 2026 GMTGLOBALINC. All rights reserved.

-01_4.jpeg)