Type | Item | Parameter |

Facility Requirement

& Appearance | Power Input | 220V 50/60Hz |

| Pneumatic System | Compressed air flow >2LPM; System supply pressure 0.6MPa-0.7MPa |

| Vacuum System | Vacuum gauge reading ≤ -80kPa |

| Environmental Conditions | Temperature: 15-35°C; Humidity: standard 70% at 32°C; Cleanliness

level: 100k Class |

| Machine Dimensions | 1000mm×1200mm×1800mm |

| Equipment Weight | 850-950kg |

| Safety Protection | Product Safety Protection | Contact grounding treatment |

| ESD Protection | Ion fan for electrostatic removal |

| Software Protection | Mistake proofing |

| Equipment Protection | Collision prevention, axis stroke limit, distance sensor |

| Operator Safety Protection | Protective goggles |

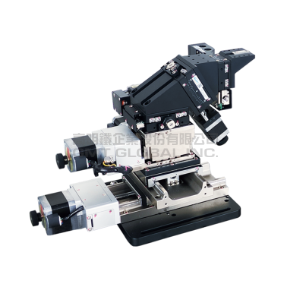

Loading/

Unloading Module | PCB Tray (5pcs, customizable) | Linear module + servo motor |

| FA Tray (5pcs, customizable) | Linear module + servo motor |

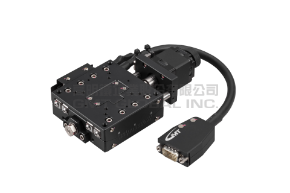

| Dispensing Module | Structure Configuration | Three-axis: XY axis linear step motor + Z axis servo motor + ball screw

module(supporting dots and lines); Positioning accuracy: 5μm |

| Dispensing system | Musashi high-precision dispensing machine, single-point (needle),

Standard 3mL capacity, other volumes customizable |

| UV Curing System | Configuration and Parameters | Dual LED light source, pneumatic shutter, wavelength 365nm |

| Clamping | Electric gripper and vacuum suction |

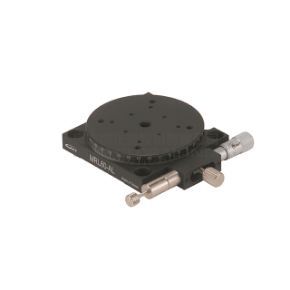

| Bonding system | Gantry System | 4 axis: XY linear step motor, Z servo motor with ball screw, θ arc swing:

0.5um repeat positioning accuracy |

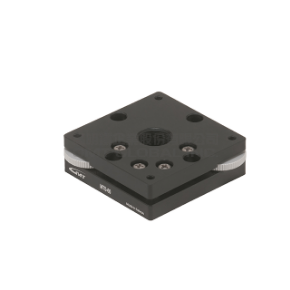

| Visual System | Automatic alignment; 500M CCD; field of view: 10.6 × 8.9mm; resolution

: 2.7μm; depth of field: 1.6mm |

| Bonding Force | Pressure sensor monitoring: 5gF |

-01_6.jpeg)